В современном производстве изделий из листового металла получение чистых изгибов и острых кромок перестало быть просто техническим требованием — это стало ключевым фактором качества продукции и ее визуальной привлекательности. От архитектурных панелей и облицовки лифтов до шкафов, дверных рам и декоративных изделий из нержавеющей стали производители постоянно ищут способы улучшить результаты гибки, сохраняя при этом стабильность и эффективность. Именно здесь важную роль играет станок для V-образной канавки.

Станок для V-образной канавки — это оборудование для обработки листового металла, используемое в основном для предварительной обработки металлических листов (таких как листы из углеродистой стали, нержавеющей стали и алюминия). Путем нарезки V-образных канавок изменяется толщина листа, что позволяет добиться точной гибки с чрезвычайно малым радиусом дуги, отвечающей высоким требованиям к внешнему виду и точности изделий в высококачественной отделке, электронной промышленности, автомобилестроении и других областях. В нем используется система ЧПУ для управления режущими инструментами, обеспечивающая точную резку по заданной траектории, что позволяет осуществлять массовое производство и повышать эффективность.

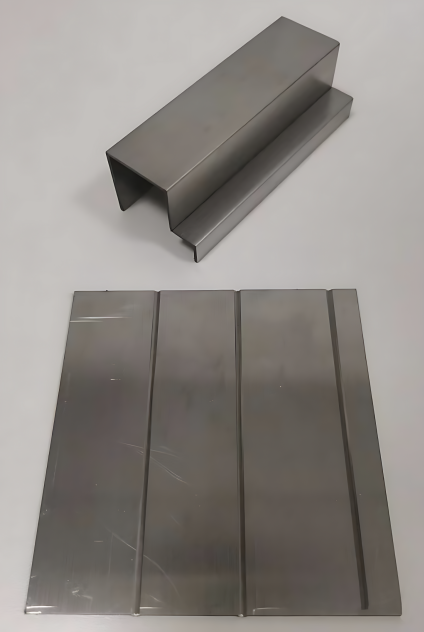

После V-образной канавки остаточная толщина материала в месте сгиба минимальна. Это позволяет листу складываться в четкий, хорошо очерченный угол, визуально более близкий к истинным 90°. Для изделий, где важен внешний вид, таких как декоративные панели или дверные рамы, эта разница сразу заметна.

Благодаря тому, что при гибке требуется меньшее усилие, пружинение значительно уменьшается. Это делает угол гибки более предсказуемым и стабильным, особенно при производстве деталей в больших партиях.

Тонкие материалы более подвержены деформации, образованию складок и царапин на поверхности при изгибе. V-образная канавка минимизирует эти риски, снижая напряжение в месте изгиба и помогая сохранить гладкую поверхность даже на тонких листах нержавеющей стали или алюминия.

Станки для V-образной нарезки канавок широко используются в отраслях промышленности, где точность, внешний вид и повторяемость имеют решающее значение, в том числе:

Архитектурные металлические панели и фасады

Кабины лифтов и дверные панели

Мебель и шкафы из нержавеющей стали

Металлические дверные рамы и наличники

Декоративная облицовка и элементы дизайна интерьера

В таких случаях V-образная канавка часто является тем фактором, который отличает стандартную промышленную отделку от высококачественного изделия.

Основной процесс включает два этапа:

1. Расположение листа

В зависимости от конструкции станка металлический лист надежно устанавливается на рабочем столе или зажимается.

2. Прокладка колеи вдоль линии изгиба

Режущий инструмент перемещается по запрограммированным траекториям, создавая точные V-образные канавки в выбранных местах. Глубина и угол канавки могут регулироваться в зависимости от толщины материала и требований к изгибу.

Основные различия между горизонтальными и вертикальными канавочными станками заключаются в направлении вращения шпинделя, обрабатываемой заготовке, конструктивных особенностях и простоте эксплуатации: вертикальные шпиндели расположены вертикально, имеют компактную конструкцию, занимают мало места и подходят для обработки тонких заготовок малого и среднего размера (например, листового металла), являются энергосберегающими и просты в загрузке и выгрузке; горизонтальные шпиндели расположены горизонтально, имеют жесткую портальную конструкцию, подходят для обработки крупных и тяжелых заготовок (например, станины станков), обеспечивают хорошее удаление стружки, но потребляют много энергии и сложны в установке. Выбор следует делать, учитывая размер заготовки, требования к точности, площадь цеха и бюджет.

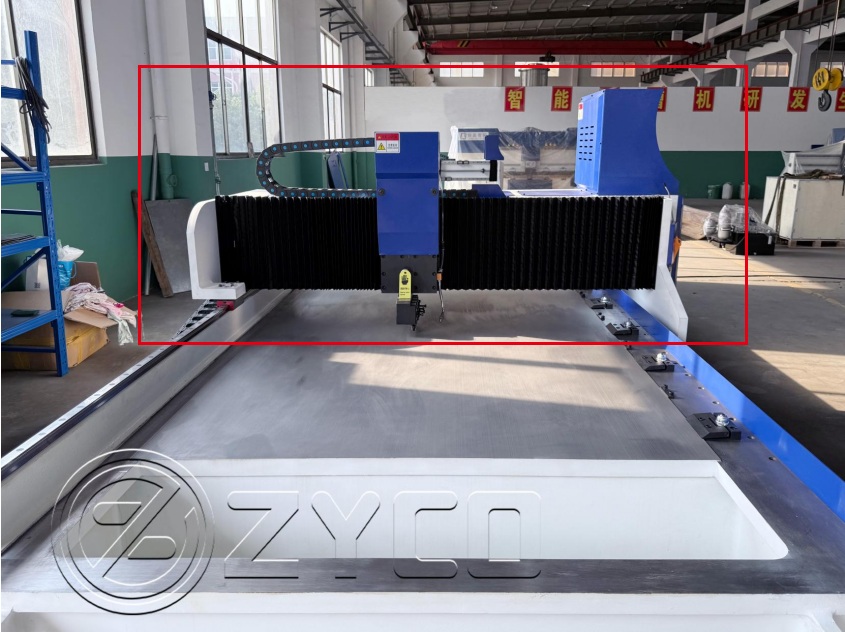

Горизонтальный V-образный канавочный станок

Sструктура:Шпиндель горизонтальный (обычно портального типа), отличается высокой жесткостью и имеет большую рабочую поверхность.

Преимущества:

1)Высокая несущая способность: подходит для обработки крупных и тяжелых заготовок.

2)Высокая производительность обработки: за один зажим можно обработать несколько поверхностей (опционально).

3)Качественное удаление стружки: облегчает удаление стружки и обеспечивает идеальный процесс обработки.

Недостатки:

1)Высокое энергопотребление: движение портала имеет большую инерцию, что приводит к высокому энергопотреблению.

2)Монтаж сложен: требуется бетонный фундамент и большая площадь.

3)Низкий уровень безопасности: Портал и держатель инструмента движутся в одном направлении с высокой скоростью, что представляет опасность для безопасности.

4)Относительно низкая точность: поверхность стола подвержена износу, что приводит к более низкой точности по сравнению с вертикальными столами.

Вертикальный V-образный канавочный станок

Sструктура:Главный вал вертикальный, конструкция компактная, общая высота относительно большая, а центр тяжести стабилен.

Преимущества:

1)Высокая точность: малая погрешность между наконечником инструмента и рабочим столом, что обеспечивает высокое качество поверхности.

2)Низкое энергопотребление: держатель инструмента имеет малый вес, а его энергопотребление составляет всего около 1/10 от энергопотребления горизонтального инструмента.

3)Простота в эксплуатации: удобная загрузка и выгрузка заготовок, хороший угол обзора и высокая безопасность.

4)Компактные размеры: Простая установка, требуется лишь ровная поверхность.

5)Применимые заготовки: Небольшие и средние высокоточные заготовки, такие как детали из листового металла перед гибкой.

Недостатки:Недостаточная поддержка крупных заготовок ограничивает диапазон обработки.

Между различными структурами нет абсолютного превосходства или неполноценности; ключевое значение имеет то, соответствуют ли они реальному продукту и способу производства.

Перед приобретением станка для V-образных канавок производителям следует оценить следующее:

Типы и толщины материалов, часто подвергаемых обработке.

Сложность размеров изделия и расположения канавок.

Требования к внешнему виду и точности изгиба

Частота изменения размера партии заказа и ассортимента.

Пространство мастерской и общая планировка

Только оборудование, действительно отвечающее производственным потребностям, может обеспечить долгосрочную ценность с точки зрения качества и эффективности.

Станок для V-образной нарезки канавок — это не просто дополнительный этап обработки листового металла, а инструмент, который напрямую улучшает качество гибки, внешний вид и стабильность производства. Для производителей, стремящихся выпускать высококачественные металлические изделия с четкими линиями и стабильной геометрией, V-образная нарезка канавок стала не просто дополнительной опцией, а неотъемлемой частью процесса.

Понимание принципа работы V-образной канавки и того, где она приносит пользу, является первым шагом к улучшению как качества продукции, так и эффективности производства.

Если вы дочитали до этого места и хотите приобрести фрезерный станок, вы можете связаться с нашей профессиональной командой ZYCO. Мы порекомендуем вам наиболее подходящую модель и предложим лучшее качество и цену.

Оставьте свой адрес электронной почты и требования, наша профессиональная команда продаж разработает наиболее подходящее решение для вас.

Авторское право

© 2026 Nanjing Zyco CNC Machinery Co., Ltd. Все права защищены

.

ПОДДЕРЖИВАЕМАЯ СЕТЬ

ПОДДЕРЖИВАЕМАЯ СЕТЬ